Quick Links

Reach Us

ORCHARD EXTRACTIONS (P) LTD,

No 71, Jahir Hussain Street,

Indra Nagar, K.K Nagar, Tiruchirappalli .

State: Tamil Nadu,

Zip Code: 620021

Country: India

E-mail: arun@orchardextractions.com

Telephone: +(91)-(431)-2455368

Fax: +(91)-(431)-2455398

Process

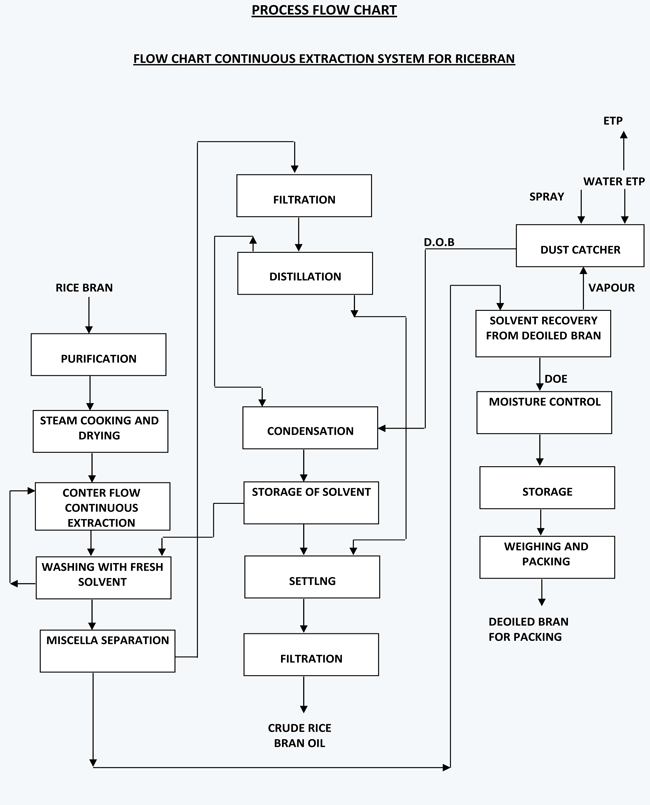

The Solvent Extraction process consists of preparation of raw material suitable to extraction, extraction of oil from Raw material, Distillation to separate oil and Hexane Desolventisation of De-oiled material, recovery of Hexane from vent air finished product bagging .the description of the each stage is as follows.

A. PREPARATION OF RAW MATERIAL:

In this stage the raw material is prepared suitable to extract oil. The Rice bran is separated from foreign Material is cooked with live steam prior to the extraction.

B. EXTRACTION:

The Cooled materials are taken in to the extractor where the Hexane will be circulated by pumps in counter current direction to the material flows. The Hexane will extract the oil present in the material and as the material passed out of the extractor the oil will be extracted and only 0.2% to 03% oil left over in the material. The Hexane and oil mixture is called as miscella, collected in a tank.

C. DISTILLATION:

The miscella collected through extraction is subjected to distillation through a series of Heaters and a Stripper to distill off Hexane. The Hexane free oil is collected in a storage tank and the Hexane vapours are a condensed by condensers and collected for re cycling in to the process.

D. DESOLVENTISATION:

The De-oiled material is heated in a vessel called Toaster to remove the Hexane present in the material prior to the begging. The material will carry the Hexane after extraction is necessary to recover the Hexane to get the Hexane free De-oiled material and the recovered Hexane will be taken back to the process.

E. BAGGING SECTION:

The Hexane free De-oiled material is separated into two grades namely Nice and Rough grades using the siever machine. These materials are packed in gunnies.